Project Description

The project was to design and develop an innovative new health monitor with built-in artificial intelligence to monitor an individual’s vital signs wirelessly and communicate with an external mesh network directly or through a phone app. We quickly developed Functional prototypes to demonstrate the technology to potential investors and strategic partners.

Rajant Health Incorporated (RHI), a division of the Rajant Corpoation, based in Malvern, Pennsylvania, is the developer of cutting-edge technology to provide on demand health insights. RHI’s intelligent products make raw data understandable and actionable for researchers, healthcare providers, and everyday users, so individuals can live better healthier lives. Revolutionizing health discovery on a global scale is RHI’s mission.

After raising $5M is seed funding, to develop next-generation health-monitoring systems that could integrate with their innovative mesh-networking technology, Rajant Health decided to bring in Paladin Robotics to be their product development team for this special project to extend their existing teams, fill-in skill gaps, and to provided expert focus on taking a smart monitor from concept to reality.

As we worked with Rajant, Paladin Robotics demonstrated expert knowledge and engineering capability across a wide range of disciplines. Paladin Robotics is well-suited to these types of projects. We excel at research and development, rapidly prototyping and iterating on design concepts.

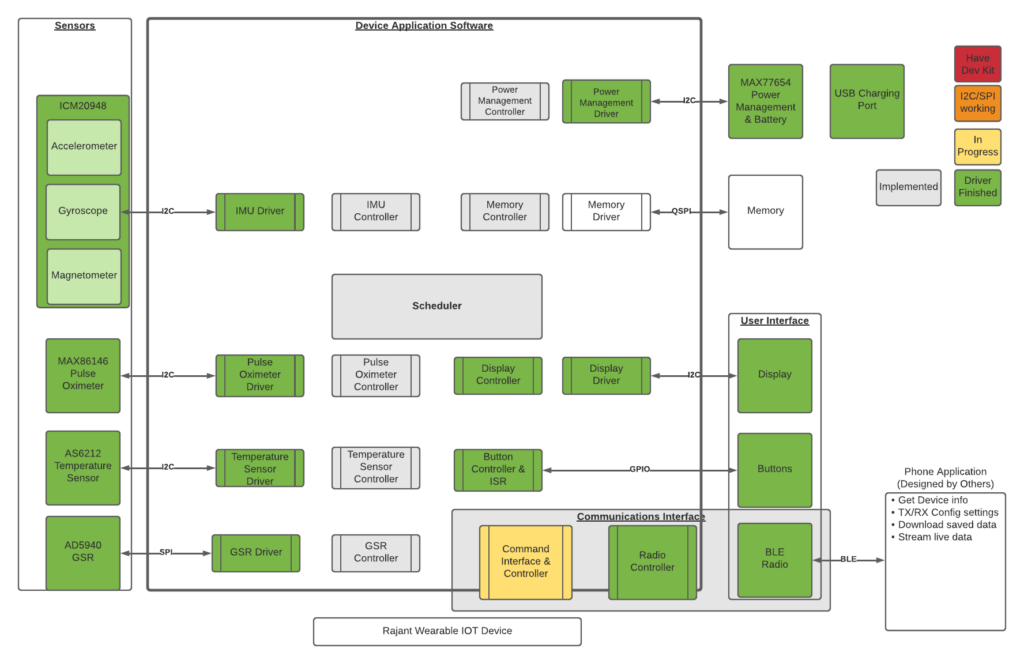

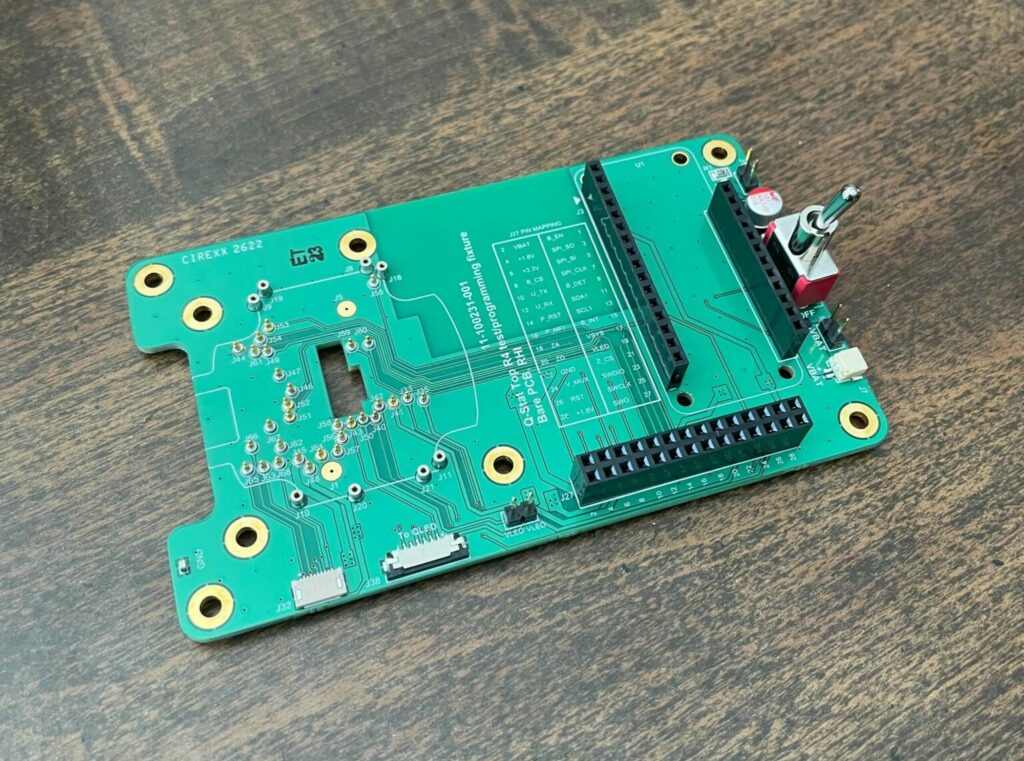

We provided a complete product development team, allowing Rajant’s engineers to focus on their existing product lines and in-house mesh networking expertise while we focused on bringing an entirely new product forward. In support of research and prototype development, we provided hardware and software design and production, UI and UX development, systems integration, and created an automated testbed to facilitate rapid iterations and on a constantly evolving product vision.

What We Did

Our team was comprised of expert engineers with specialties in each of the following disciplines:

- Mechanical Engineering

- Electrical Engineering (Software)

- Electrical Engineering (Hardware)

- Instrumentation and Control systems

- Internet of Things

- Embedded Systems

- Project Management

Over the course of this product-focused research and development project, we touched on most of our core competencies:

- Research & Development

- Initial Requirements Development

- Component Selection

- Detailed Project Plans

- Initial BOM estimates

- CAD design and simulation

- Prototyping

- Parts design and fabrication, including 3D printing

- Custom PCB design, fabrication and testing

- Software development

- UI/UX Development

- Digital signal processing

- Troubleshooting

- Manufacturing & Assembly

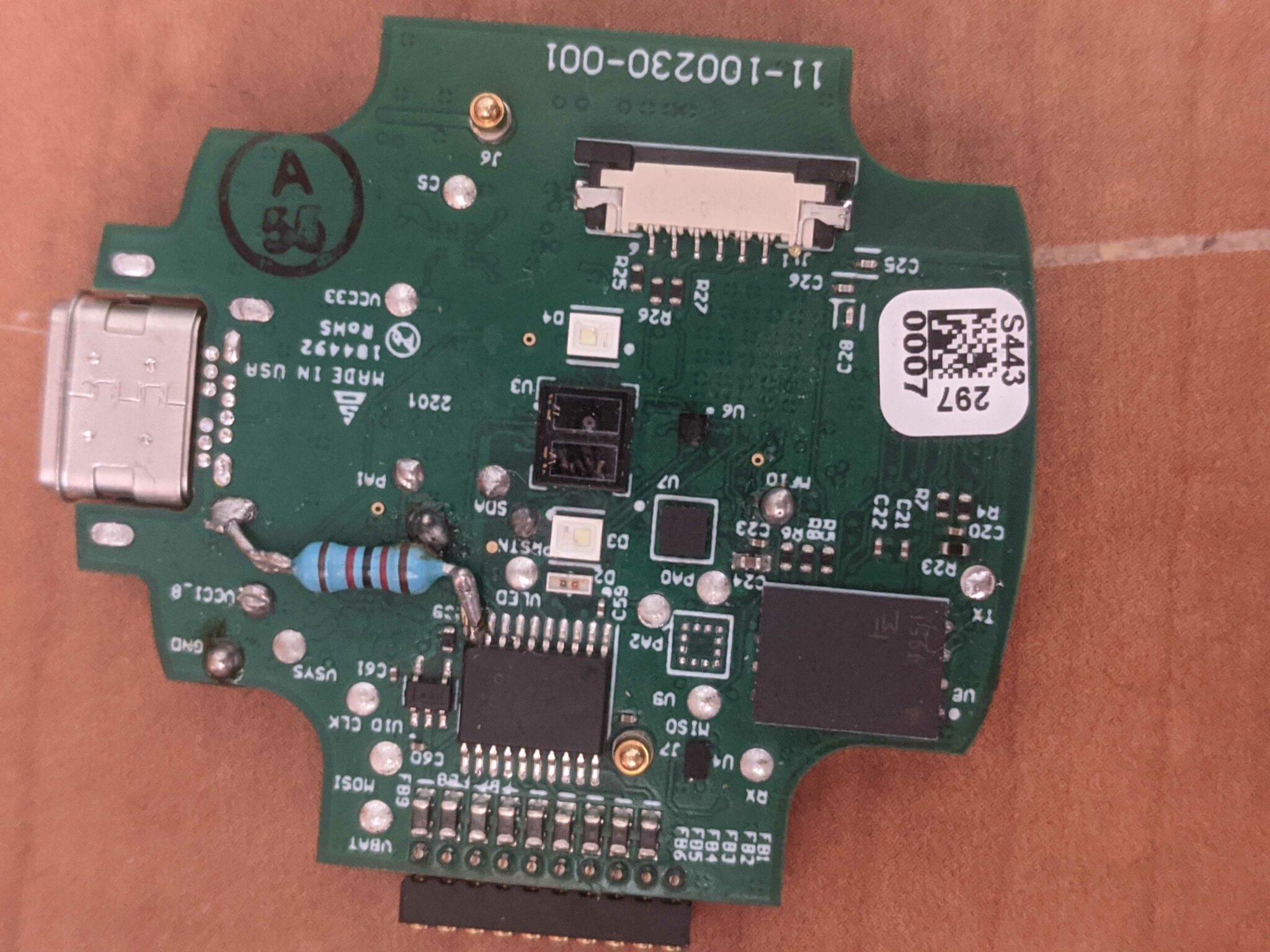

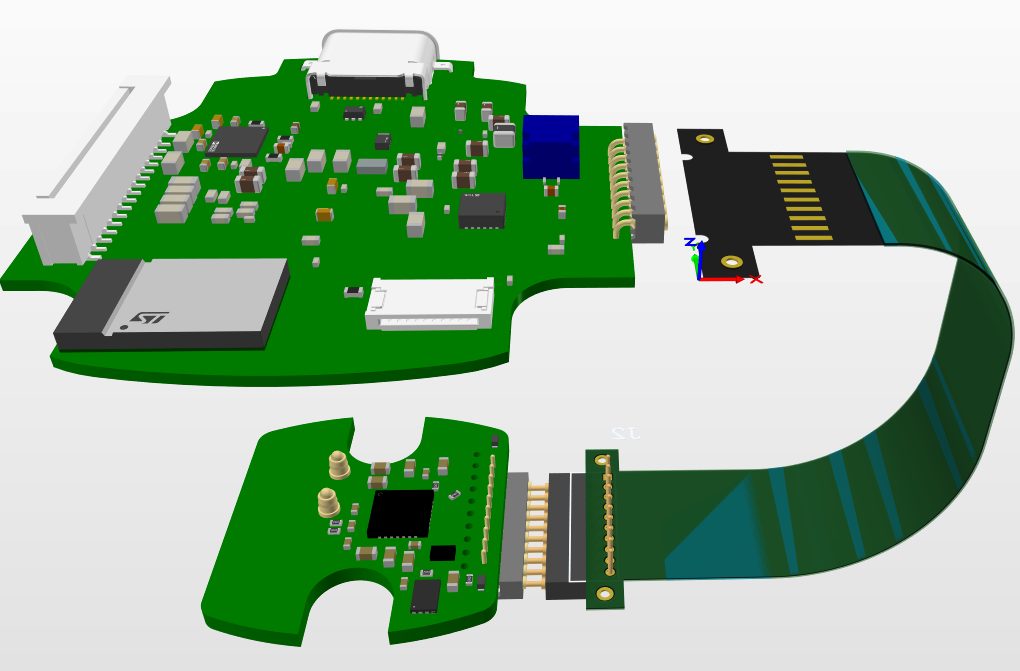

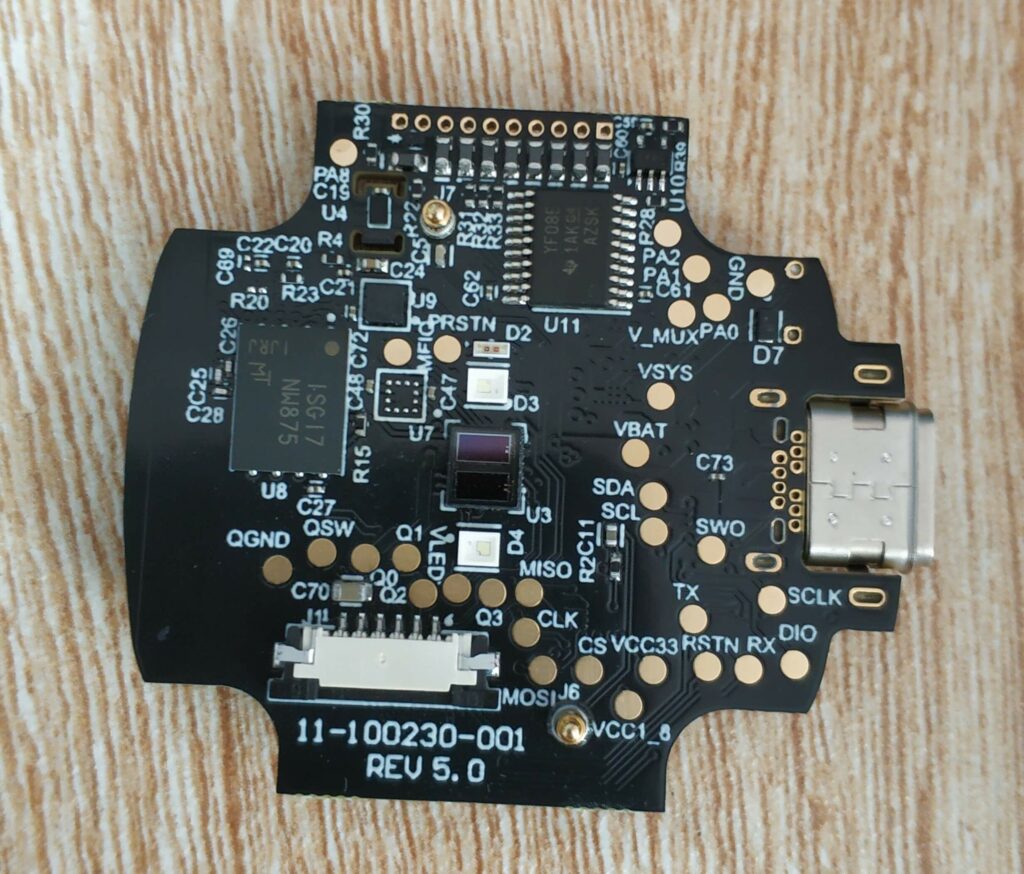

We started with nothing more than a concept and some off-the-shelf development hardware. Over the course of the following year, we designed and produced multiple revisions of custom printed circuit boards in support of the evolving product vision.

This wearable health monitor integrated several of medical-grade sensors.

Photoplethysmograph (PPG) – A PPG is an optically obtained plethysmogram that can be used to detect blood volume changes in the microvascular bed of tissue. We developed the PPG using a wrist-worn pulse oximeter using red, green and IR lights which illuminates the skin and measures changes in light absorption. With this subsystem, we were able to determine heart rate, oxygen saturation (SPO2) as well as derived values from those measurements. We integrated accelerometers to compensate for motion artifacts in the PPG.

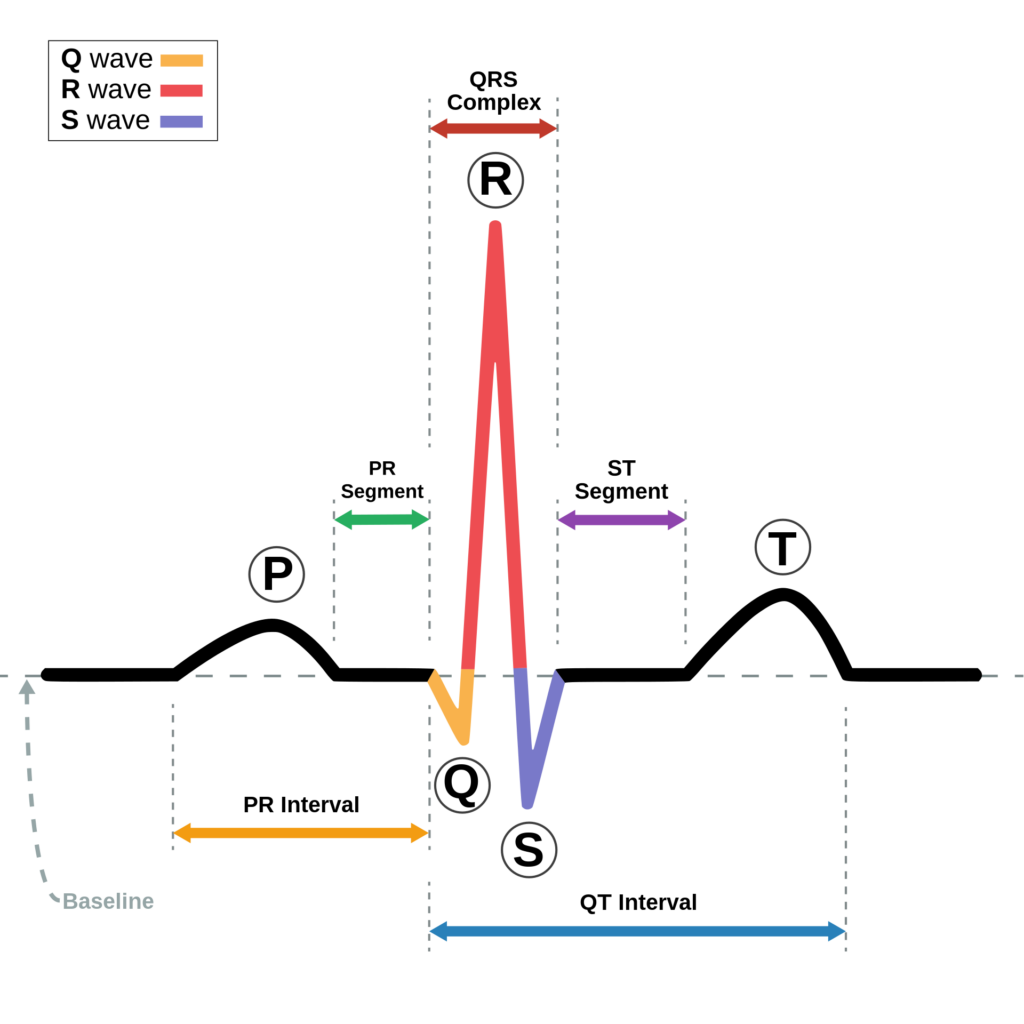

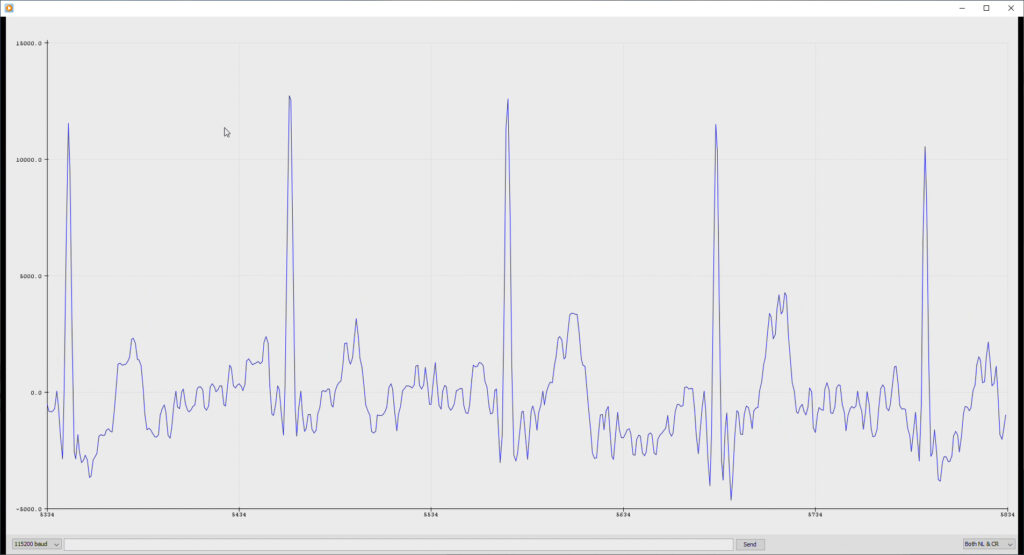

Electrocardiogram (ECG) –An electrocardiogram provides a graph of voltage versus time of the electrical activity of the heart using electrodes placed on the skin. These electrodes detect the small electrical changes during each heartbeat

Figure 7: Actual data from our working ECG

Clinical-grade temperature sensor – this subsystem included the electronics and software drivers as well as the mechanical connections to conduct heat from the skin to the sensor for an accurate measurement.

Inertial Motion Unit (IMU) – this subsystem included a 9-degree-of-freedom integrated compass, gyroscope, and accelerometer, which when combined with the integrated mesh network, allowed the wearer’s heading, position, and motion to be monitored as well as estimating their activity level.

Power Management Integrated Circuit (PMIC) – this subsystem provided power rails at multiple voltages, as well as monitoring the Li-po battery and maintaining its charge.

Display – this subsystem provided status messages to the user as well as integrated button.

User Interface – this multimedia subsystem included the development of the menus, displays, and alarms, as well as multi-function button drivers, and an embedded led ring in the bezel to communicate a number of special status conditions.

Bluetooth Low Energy Radio – As a wireless focused device, we developed a BLE radio link capable of connecting to a smart phone app, as well as to the Rajant mesh network. Additionally, the device functioned as a hub allowing multiple other sensors to connect through the device to the rest of the network.

Software – We were solely responsible for the development of the device software and for the development of the communications protocols. Our development work ranged from the lowest level of device driver all the way up to the application software operating the wearable device. We also developed several PC-based utilities for testing and diagnostics.

Hardware – We were solely responsible for the PCB layout and design. We also worked on the mechatronic design of the swappable modules and the swappable band.

Testing Apparatus – In addition to the above, we also developed a custom PCB to provide automated testing and programming for manufacturing.

We are particularly proud of the wrist-mounted ECG, which we took from idea to functional prototype in just 12 weeks. We not only implemented this system, but completely redesigned the wrist worn device to swappable top and bottom modules to allow for new functions to be integrated and new sensors to be developed for the bottom module. We were able to complete this in time for a demonstration to a large regional hospital system delivering our work a week ahead of the initial deadline.

Having a demonstration at this event was identified as a critical goal for Paladin Robotics with only three months lead time to completely redesign the wearable system to a modular top and bottom module with a functioning ECG. Paladin Robotics accepted the challenge and quickly brought the team together on an aggressive project plan. We delivered a tested, working prototype (see photos below) just in time. Following the demonstration we continued to develop the design to take us one step closer to manufacture-ready first article and started the process of handing the design work over to Rajant Health’s growing engineering team.

Ultimately, we’ve helped Rajant produce working proof-of-concept prototypes, suitable for small trials and market research, recruit investors and strategic partners, transition the work products to their team, and carry the project forward to success. We were key contributors in helping Rajant hit critical milestones. The prototype pictures shown here represent a huge amount of effort and engineering know-how.